Other products:

- Chamber furnaces

- Belt continuous furnaces

- Roller continuous furnaces

- Other continuous furnaces

- Vacuum furnaces

- Nitriding lines and furnaces

- Pit and Bell furnaces

- Special furnaces

- Washing machines

- Accessories

Continuous conveyor belt furnaces for the reduction of oxides of metallic powders

The heat treatment at high temperature performed with this type of furnace, through appropriate gas atmospheres, produces modifications in the chemical composition on the surface of the treated materials.

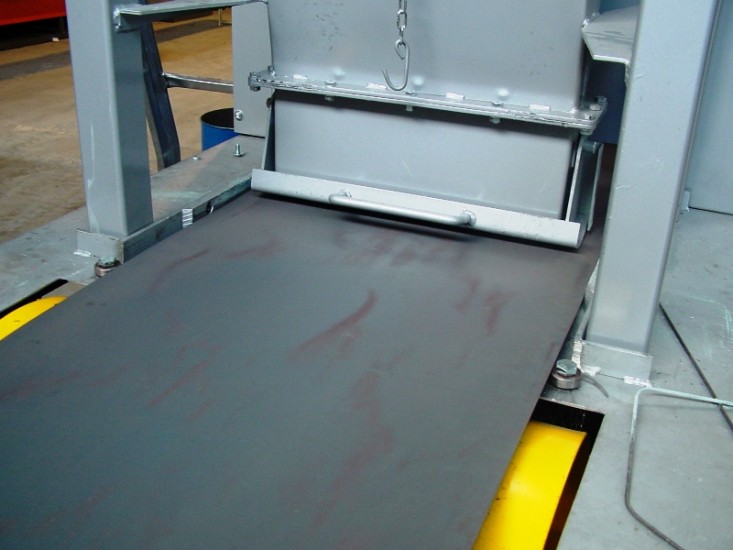

This is the case of the continuous conveyor belt furnaces for the reduction of oxides of metallic powders (e.g. copper, iron, stainless steel), where the transporting means is constituted of simple heat resistant sliding steel sheet belts and the protective gas inside the furnace is strongly reducing.

The continuous conveyor belt furnaces for controlled blue-black colored oxide, constituted of iron oxide that is resistant against atmospheric corrosion, is carried out on sintered material in the presence of superheated steam. The porous materials that are formed by sintered powder particles also become waterproof and acquire greater hardness (e.g. pistons for refrigeration compressors).

Along with this treatment, annealing also takes place and this allows to increase the magnetic permeability of the laminar packs, constituting of the previously indicated magnetic cores. In this treatment, it is possible to use the superheated steam as well as the exothermic gas that is produced by burning the air/hydrocarbon fuels.

Gallery

Heat treatments & materials:

Carbonitriding

Carburizing

Washing

Hardening

Request of information

Contact usViale dell’Industria 7, Colle Umberto (TV) Italy

Holding Company: CIEFFE INTERNATIONAL AG, Zug

sales@cieffe.it

powered by neiko